I first saw 3D printing at work in the movie Mission Impossible II starring Tom Cruise, which debuted 13 years ago. It seemed like at every turn, some spy was printing out a life-like 3D facial mask to impersonate his enemies.

Action flicks tend to preview near-future technologies, and 3D printing has gone from science fiction to an over-hyped but cutting edge research area since MI 2. The printers in question print 3D objects out of plastic or concrete instead of flat images on paper using ink. To show why the subject seems to have captured popular imagination, here is a short list of objects that may be printed in the near or distant future, according to recent articles:

Our guest for this podcast is Kenneth Sloan, Ph.D., professor in the Department of Computer and Information Sciences within the UAB College of Arts and Sciences, and director of UAB’s

3D Print lab. As described in an

article by UAB Magazine's Matt Windsor, 3D printing may have applications in areas as diverse as medical implants, gaming, archeology and crime fighting. As Dr. Sloan says, there may soon be a 3D printer in every kitchen, and available in designer colors, but who knows what we will use them for.

Show notes for the podcast

1:25 Instead of ink, one kind of 3D print head pushes out extremely thin layers of superheated material that instantly cool to hold a desired form. Most of the 3D printers at UAB lay down layers of melted plastic 1/100th of an inch thick. They then move the print head up a bit and do it again, until the 2D layers stack up into a 3D object.

2:27 A second kind of 3D printing cures material in layers. You start with a box full of powder, and the printer lays down liquid in layers that hardens the power in the desired pattern. What you end up with is a box full of powder, with the desired object inside of it. You open the box, grab the object and shack of the lose, uncured powder. Interestingly, since concrete is hardened by combining liquid with powder, this has enabled researcher to 3D print objects in concrete.

3:30 An important challenge in 3D printing is that engineers must often design and print out a framework right alongside the target object so that the object doesn't collapse have way through being printed.

4:13 3D printing technology has been available for 20 years, but the computational power is just arriving now to make it useful and available to all. The advent of cloud computing meant that most researchers can now afford to program complex combinations of objects and supporting frameworks. Otherwise, 3D printers are made of standard tinkerer elements like small electric motors, sprayers and heating elements that have been around since the 1950s.

4:38 What makes 3D printing require computing power are the calculations about where to lay down solid material in space as you build the object in layers, as well as the translation of spatial relationships from a 3D model to a series of 2D slices.

6:05 For many years, engineers have looked at 3D graphical displays on computer screens when designing prototypes. They work through a series of rapid design changes for an invention, testing and rethinking versions along the way. 3D printing allows engineer to print out the object at each stage in rapid prototype design. They can test fit it against other parts of whatever they are creating. They can roll it around in their hands. 3D printing allows for the fast manufacture of quick, cheap, multiple versions of a prototype invention in plastic to solve problems before fabricating it from an expensive metal for instance.

.jpg)

7:03 3D printing enables the creation of complex objects that no other process can create. There are several examples on Dr. Sloan's website that you cannot take apart, and that you could not assemble out of pieces in the first place. By printing interlocking pieces in layers, the final product is made of moving pieces that cannot be assembled or dis-assembled. Picture a door that is one solid piece with it hinges. The door swings on the hinges, but you can't remove the hinges. Fun examples of this kind of object include puzzles. Dr. Sloan mentioned that one MIT student had even designed a

3D-printed a Rubik Cube, a single, interlocking movable puzzle as opposed to the original, made of separate pieces that snapped together.

9:24 Plastic and concrete were the first materials used in 3D printers because they are easy to melt or harden quickly into durable materials. Plastic melts easily and can be shot through a print head. Concrete starts as a powder and object can be shaped by selectively getting it wet. The interesting thing is that any substance that meets either of these criteria might eventually be 3D printed, from ceramics to metal to glass to chocolate.

11:08 Dr. Sloan's original area of expertise was in computer graphics. The field had delivered tremendous value to engineers by developing the capability to display 3D digital images of desired objects on computer screens. That said, researchers had long wished that they could cheaply 3D print digital designs. With every decade, a "zero has been chopped off the price" of 3D printers, and now most labs can afford one.

12:13 Beyond assembling equipment, Dr. Sloan has reached across UAB to offer a 3D printing service of sorts to researchers in many disciplines. With a main mission of educating students in 3D printing, his lab might have been satisfied with using "hobby level" printers, or with sending out big jobs to specialty "print farms." By hatching collaborations across campus, he has been able to centralize equipment costs and expertise to offer more advanced 3D printing to many research efforts that couldn't do it alone. By making this offer, his lab has enjoyed a steady flow of inquiries from researchers proposing to use 3D printing in wasy he never could have imagined. Meanwhile, his student now have unparalleled access to real world design projects.

.jpg) |

| Lamina cribrosa |

14: 26 An example of an interesting, unexpected project was the 3D printing lab's collaboration with the

UAB Department of Ophthalmology. The lab was able to 3-D print a computer model designed by eye researchers of part of the optic nerve, the lamina cribrosa, known malfunction in the development of glaucoma. Apparently, our eyes our sealed, with a certain pressure maintained inside. This is complicated by the need for the optic nerve to pass through the outer membrane of the eye as it carries information about images from the lens into the brain for processing. Making this possible is the lamina cribosa, a web-like mesh through which the optic nerve fibers can pass out of the eye without losing pressure. This feature of the anatomy is about two millimeters across, but Dr. Sloan's team was able to 3D print an eight-inch version. This enabled the research team to pick it up, look through it and roll it around in their hands for the first time. Since then, Dr. Sloan has watched as a series of eye researchers, including his wife, UAB anatomist,

Christine Curcio, Ph.D., have picked up the model, spun it around and said,"...interesting, I never realized that XX."

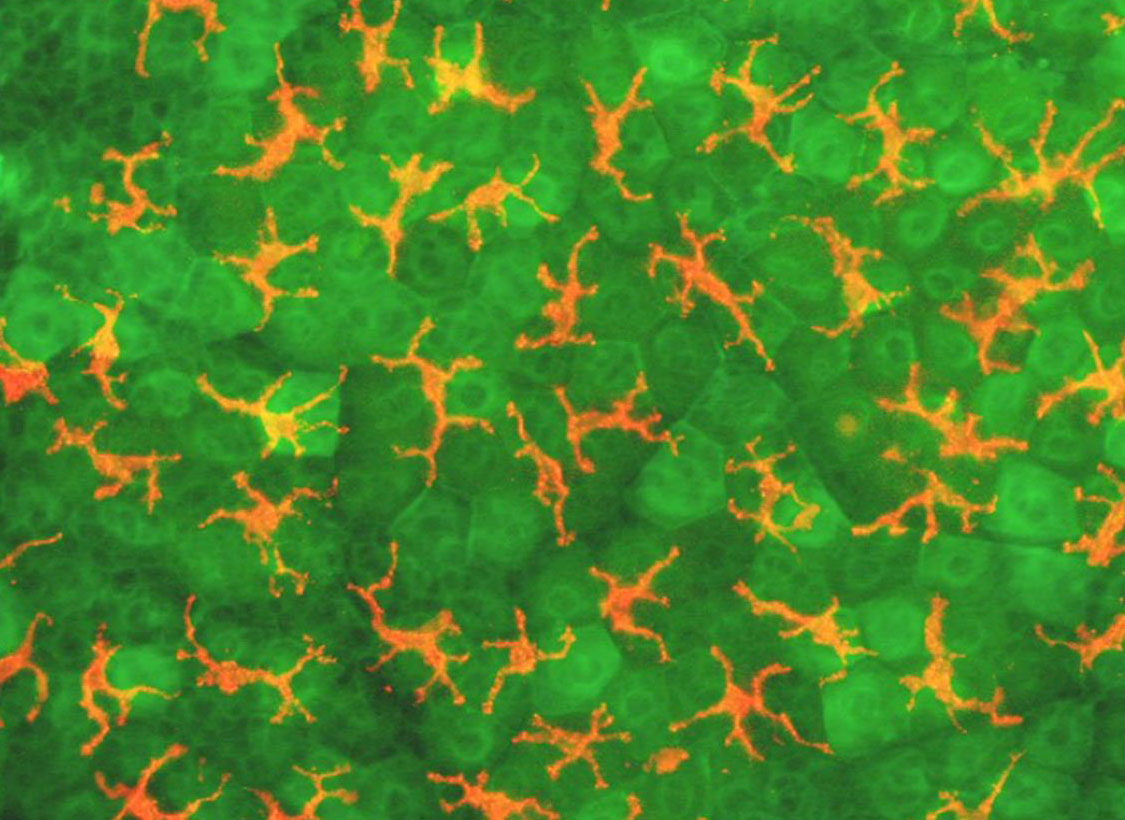

16:59 Dr. Sloan also highlighted the ability of 3D printing to be useful to bioengineers seeking to design scaffolds. The body has an amazing ability to

regrow skin, bone or muscle lost to injury or disease, but it often needs help. His lab is involved in current UAB research projects seeking to design of mats or scaffolds or weaves of material that act as a guide and support for tissue trying to grow back together in an orderly fashion. 3D printing may be especially useful in creating scaffolds out of biodegradable materials. That would enable surgeons to implant a scaffold that aids in tissue regeneration without requiring a second surgery to remove the scaffold later. It would simply dissolve about the time it was no longer needed. Dr. Sloan's lab has one printer that prints in a biodegradable, nontoxic material, and there has been a steady stream of researchers from the medical end seeking to build it into research projects.

18:32 3D printing will be valuable to regenerative medicine for the same reason it is useful in rapid prototyping. It lends itself to creating a single custom implant for each patient, versus technologies that require mass production of one-size-fit -all implants to break even.

19:32 Dr. Sloan believes that it will be possible in the next five years for biotechnicians to 3D print skin to cover wounds and burns, knee cartilage and heart valves. These are examples of the more straightforward, uniform tissue types that lend themselves to current 3D printing technologies. Unfortunately, he said there is also a great deal of hype surrounding 3D printing right now, and stories that predict the imminent arrival of printed, complex organs with intricate cellular structure are not realistic. These structures would require technologies that 3D print with a nanoscale resolution, and are still a long way off.

21:50 Beyond medicine, a recent article in Discover Magazine talked about how 3D printers may one day print out meals for future astronauts on long spaceflights. Dr. Sloan said burgers and pizza would be on the 3D printing menu, but not steak. The reason for this are the same ones that determine the field's ability to print out skin but not a brain. Burgers and pizza be printed out of somewhat homogeneous, simple materials that hold their form in layers as they are printed and then cooked. A pizza printer might have five printer cartridges that spew layered shapes that bake into a pizza. Steak is tissue, with a complex microstructure beyond the reach of current technologies.

24:40 Dr. Sloan this week attended the

Inside 3D Printing Conference in Chicago, which included an exhibit of 30-foot high concrete sculptures made using 3D printers. He is currently seeking collaborations with artists and sculptors who wish to 3D print fantastical forms by curing concrete out of powder. Layer-by-layer printing may make possible the creation of interlocking, complex sculptures that would fall apart in mid-assembly if made any other way.

26:06 Moving from art to architecture, Dr. Sloan said he has seen reports of researchers experimenting with the idea of 3D-printed buildings. If one can print a 30 ft by 30 ft sculpture, it may be possible to print a 300 ft by 300 ft building. Furthermore, builders may one day dispatch a team of mobile robots with built-in 3D printers to assemble different parts of a building at the same time. The same idea goes for shooting robots to the moon that could mine local materials and and then 3-D print a moon base before the people even arrive. An advantage of large-scale 3D printing would be that you no longer have to build a structure out of pieces (nails, beams, etc.). That leaves the architect free to design any structure that will stand once complete.

28:23 Dr. Sloan hesitated to predict how we might use 3D printers in the future. He said he is old enough to remember when personal computers were just a pipe dream. As their advent approached, articles mistakenly predicted that we would use them to store our recipe files and to tell us what to make for dinner based on what was in the fridge. "Who knows how we will use 3D printers around the house?" If it gets cheap and useful enough, people will invent their uses for it.

Here are a few more, recent 3D printing articles from around the web:

New Scientist: Windows aims to open 3D printing to the masses

CNBC: How 3D printers are reshaping medicine

Time: Chicago 3D print shop open for business

.jpg)

.jpg)